What does it mean for manufacturing to be democratized? And how do we help it happen?

Much noise has been made about the maker movement, “long-tail” manufacturing, and the 4th Industrial Revolution. Visionaries differ on the exact definitions and significance of each of these, but the fundamental concept is that manufacturing is getting smarter, more customized, and more decentralized. Advanced fabrication techniques and accessible design tools are increasingly available to makers, tinkerers, inventors, and small businesses. In particular, the costs of rapid prototyping and small production runs dropped by roughly one to two orders of magnitude in the decade from 2005 to 2015. There has been a step-change in the economics and speed of small-scale manufacturing.

This is the beginning of a paradigm shift. And one dawning consequence is an enormous reduction in the barriers to entry for making things.

For a century, manufacturing has been primarily the domain of large corporations employing designers, engineers, laborers, and their ancillary support like supply chain specialists and legal departments. It has been necessary for large corporations to produce large quantities of identical goods to achieve economies of scale. For the most part, niche items and customized products could only be made by experienced artisans or high-cost boutiques. In both cases, specialization or a perception of superior quality is required to command premium pricing and maintain competitiveness against cheaper mass-manufactured goods.

In that manufacturing paradigm, the options available to consumers are expensive artisanal products, or cheap mass-produced products, or some intermediate cost/quality compromise in between. Both of these 20th-century manufacturing techniques have high barriers to entry: some combination of experience and scale is required to make things. It has always been necessary to possess some level of training, connections, and capital to manufacture most goods.

The society-altering impact of new 21st-century digital fabrication is allowing unconnected, unfunded amateurs to make complex products for themselves or for sale. This change required many critical technological and cultural developments over the last two decades:

- Internet commerce developments such as secure payment processing and auction sites

- Crowdfunding

- Popularization of online wikis, forums, and blogs for knowledge-sharing

- Open-source development cultures that value iteration and evolution of designs

- Structured collaboration tools such as GitHub

- Creation of generalized low-cost development platforms such as the Arduino microcontroller line and associated programming IDE

- Low-cost or free software licenses for powerful design tools such as Eagle and Fusion360

- Development of foundational open-source code elements such as GRBL motion firmware

- Relative ease of outsourcing subcomponent fabrication overseas to vendors willing to serve small markets

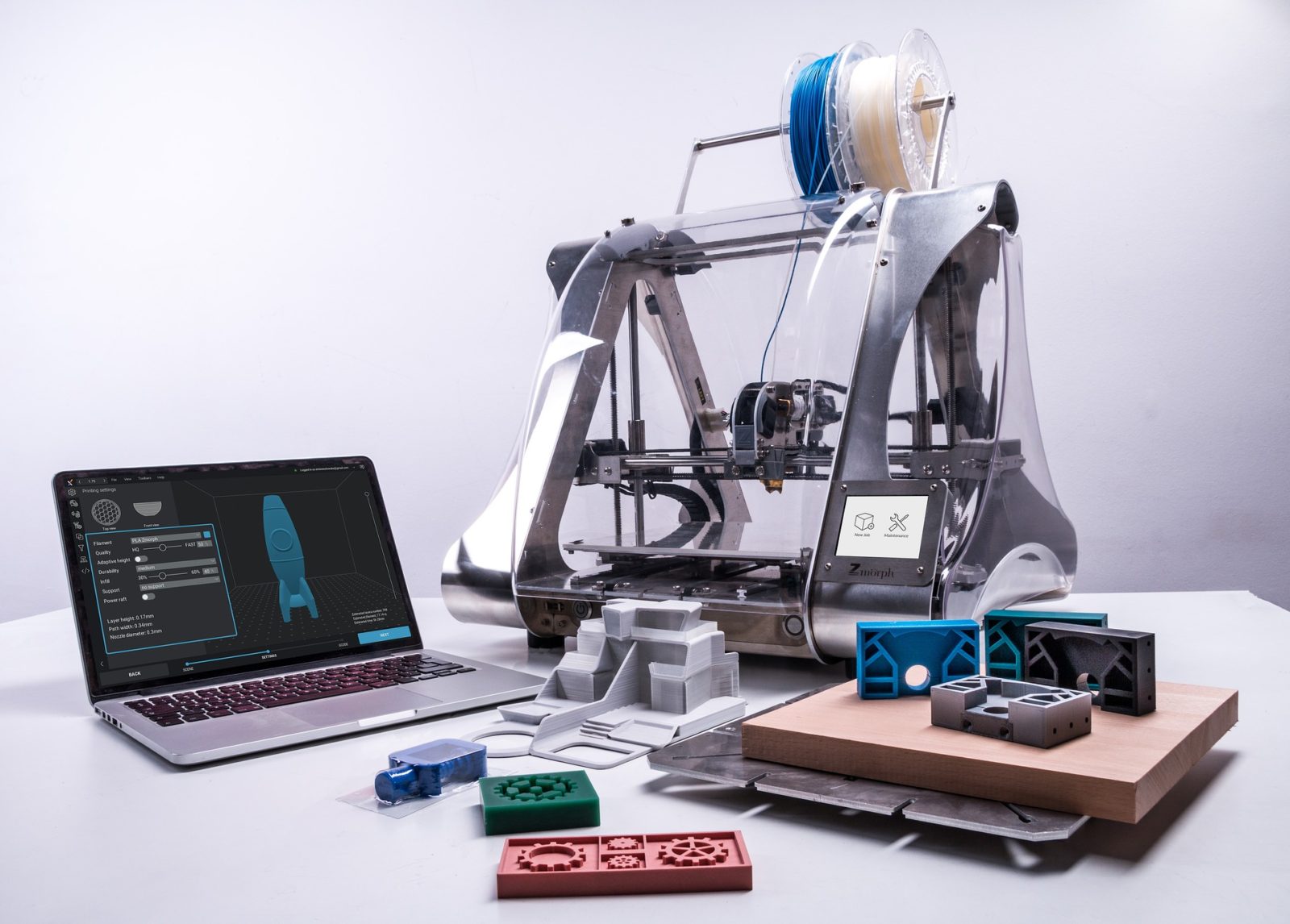

All of these elements have gradually combined to decimate the cost and complexity of creating a custom product or solution. Affordable 3D printing sits at a critical nexus of this rapid shift: printers are both an end-user of these tools and a massive enabler to building other things.

3D printing has greatly reduced the barriers to entry for making things, which necessarily means it has punctured the barriers to entry for making 3D printers. This is the beauty of the RepRap concept for self-replication: if you have access to the internet and a few hundred dollars, you can build a 3D printer. And then you can use it to make more 3D printers. And then you can make wonderful things that weren’t even possible a few decades ago.

This relative ease of building 3D printers is generating enormous good, but also some unexpected downsides. For example:

- 3D printer hardware has experienced a rapid “race to the bottom” with often unsustainable and unrealistic price competition. This has caused many high-profile product launch flops, particularly via crowdfunding campaigns, and made it harder for quality products to compete with flash-in-the-pan hype.

- The sum total of all 3D printer technology knowledge and competence increases greatly every year, but the average level of technical competence across all users is in decline. First-time printer buyers are ever more likely to be casual users rather than tech-savvy early adopters. The sector is no longer the sole domain of large companies and small groups of “expert amateur” makers. These new users generally do not grasp the large difference in reliability and safety between lowest-cost 3D printer designs and more familiar mass-consumer appliances or DIY tools.

- The decrease in technical barriers to entry means less overall technical competence is required to build a working printer or launch a printing-related product. Subcomponent design and complex parts selection is no longer strictly required: entire commercial ecosystems have developed around selling popular component to designers who lack the means to properly specify components. 3D printer design appears very nearly “plug and play” to amateur makers. But it is not so simple. That means a higher proportion of printers will incorporate poor designs, experience predictable performance problems, or lack adequate safety features.

- The rise of “cloners” — companies that sell cheap copies of open source designs, with or without complying with associated open source licenses — may produce competitive pressure against certain types of innovation. Companies that do not invest in product development can under-price innovators and manufacturers of higher-quality products. Most new consumers of 3D printing hardware do not have sufficient familiarity with the technology to properly differentiate between these products. So a large fraction of the consumer 3D printer market as of 2018 is composed of cloners selling variants of older amateur open source designs. Thousands of small companies and hobbyists do generate continuous incremental technology steps, but ventures with sufficient funding and engineering / R&D acumen to make big innovative leaps are largely avoiding consumer 3D printing.

These challenges are growing pains for a new technology sector. Exponential growth of disruptive technology will always be turbulent. Despite these issues, on balance, the picture for consumer and hobbyist 3D printing is quite healthy. The quality/price ratio of low-cost printers seems to have finally found a floor, and a $200 entry-level product is now superior to the $1,000 printer of only a few years ago. A vibrant and robust parts ecosystem has now grown up largely independently from large corporations. Such organic growth of countless small players is inherently resilient against setbacks and external disruption. But it is also tumultuous and chaotic to a degree.

Economics difficulties aside, a key remedy for many of these issues is the development of quality technical resources for users and designers to learn the state of the art. The hobbyist community has accumulated vast stores of tribal knowledge, experiential wisdom, and qualitative theory over the last decade — but this is largely scattered across hundreds of thousands of forum threads and blog posts. Some central resources like the RepRap Wiki do exist, but they serve largely as a short-form summary of concepts and designs, not comprehensive explanations of theory and design practice. Other knowledge-sharing attempts primarily target new users and focus on basics. There is a lack of technical education material for engineers and advanced users.

Makers prefer making to documenting, unsurprisingly.

Unfortunately, the dramatic decrease in cost of entry for 3D printer construction has also produced a plethora of mediocre entrants to the field. The open-source reference designs contain many shortcomings that are copied into low-cost clones. Engineering seems to be primarily a matter of trial, error, and organic adoption of heuristic solutions discovered by the user community. This is both a weakness and a strength. Democratizing manufacturing allows rapid uptake of good ideas, but also generates and disseminates far more mediocre ideas.

Very little 3D printer engineering design rigor is present at the consumer price point. Thus the motivation for this book series — to communicate the underlying design principles that govern 3D printers. In addition to informing designers of consumer-grade printers, this should serve to arm the hobbyist and consumer to better identify quality designs and troubleshoot poor performance.

Minimizing repeat mistakes and duplicated effort is enormously valuable in accelerating technology development. Thus, the purpose of the 3D Printer Engineering series of books is to explore technical concepts in depth and clearly explain both the “how” and “why” of good 3D printer design. There are so many different technologies involved that this will require years of writing, and no doubt many omissions of useful info and anecdote for the sake of bringing a chapter to completion.